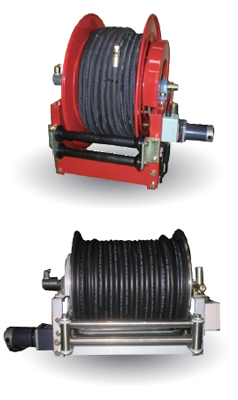

Power Rewind (Series 1000) | Hose Reel

HOME > PRODUCTS > Power Rewind (Series 1000)

Uses : Fuel dispensing,Fire protection,Water supply,Chemical transfer etc.

Design & Structure

- Lightweight compact reels designed for long lengths of hose in power rewind.

- If it is power rewind,Motor is installed outside of the Reel.

- Power rewind reels are not supplied with switch but can be ordered separately

- Chain and sprocket drive powered by electric, hydraulic, or compressed air motor.

- Direct crank rewind is permanently attached(Direct crank rewind is removable when you need.)

- Roller guides are option(Specify roller position when ordering.)

- Brake System:cam-lock drag brake or spring actuated pin lock(Supplied with spring actuated pin lock as standard)

- Full flow shaft and swivel

- Standard inlet 90° balanced pressure swivel joint(NBR Packing)

- Inlet & Outlet connection threads are female NPT (Other threads are available when you request)

- All materials are carbon steel as standard (Stainless, Aluminum and other materials are available when you request)

- Type of Bevel Gear crank rewind is options(Pinion brake as standard)

- Option:Automatic guide,Speed controler,Clutch is available.

- Series 1000 reels are supplied without hose. Hose assemblies will be quoted according to your request.

- Other specifications are available.

Painting:powder coat.

Specification

| Available Hose specifications | Max Pressure | Max Temperature | Rewind Type | Installation | ||

|---|---|---|---|---|---|---|

| Size(Inch) | Hose Material | Length(MR) | ||||

| 1/4 inch ~1/2 inch |

Rubber(1W/B) | 50MR~100MR | 2900psi/200bar | 212℉ (100℃) | Manual & Power Motor | Floor |

| 160ft~300ft | ||||||

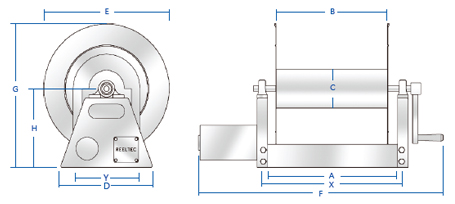

| MODEL NO. | HOSE CAPACITY | REEL DIMENSIONS | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I.D | O.D | LEN GTH | A | B | C | D | E | F (MANUAL) |

F (POWER) |

G | H | X | Y | |

| mm inch | mm inch | meter feet |

mm inch | mm inch | mm inch | mm inch | mm inch | mm inch | mm inch | mm inch | mm inch | mm inch | mm inch | |

| S106-9 | 6.5 1/4 |

13 0.5 |

50 165 |

360 14.2 |

200 7.9 |

200 7.9 |

350 13.8 |

380 15 |

520 20.5 |

685 27 |

430 16.9 |

240 9.4 |

320 12.6 |

300 11.8 |

| S106-19 | 6.5 1/4 |

13 0.5 |

100 300 |

540 21.3 |

380 15 |

200 7.9 |

350 13.8 |

380 15 |

700 27.6 |

865 34.1 |

430 16.9 |

240 9.4 |

500 19.7 |

300 11.8 |

| S109-9 | 9.5 3/8 |

17.5 0.6 |

50 165 |

460 18.1 |

300 11.8 |

200 7.9 |

350 13.8 |

380 15 |

620 24.4 |

785 30.9 |

430 16.9 |

240 9.4 |

420 16.5 |

300 11.8 |

| S109-19 | 9.5 3/8 |

17.5 0.6 |

100 300 |

710 28 |

550 21.7 |

200 7.9 |

350 13.8 |

380 15 |

870 34.3 |

1035 40.7 |

430 16.9 |

240 9.4 |

670 26.4 |

300 11.8 |

| S1013-9 | 12.7 1/2 |

20.6 0.8 |

50 165 |

560 22 |

400 15.7 |

200 7.9 |

350 13.8 |

380 15 |

750 29.5 |

885 34.8 |

430 16.9 |

240 9.4 |

520 20.5 |

300 11.8 |

| S1013-19 | 12.7 1/2 |

20.6 0.8 |

100 300 |

810 31.9 |

650 25.6 |

200 7.9 |

350 13.8 |

380 15 |

1000 39.4 |

1135 44.7 |

430 16.9 |

240 9.4 |

770 30.3 |

300 11.8 |

※The specifications are subject to be changed without previous notice for improvement.