Power Rewind

(CR2000-Series) | Cable Reel

HOME > PRODUCTS > Power Rewind (CR2000-Series)

Specification

| Cable specifications | Allowable Current | Rewind | Installation | |||

|---|---|---|---|---|---|---|

| Square | Cable Material | Core | Length(MR) | |||

| 6.0 ~ 10.0 | VCTF | 3 ~ 4 | 50MR~200MR | 30~50A | Manual & Power Motor |

Floor |

| 160ft~600ft | ||||||

Design & Structure

- Heavy duty steel construction and compact design is suitable for long lengths of cable in power rewind.

- If it is power rewind, motor is installed outside of the Reel.

- Power rewind reels are not supplied with switch but can be ordered separately

- Chain and sprocket drive powered by electric, hydraulico, r compressed air motor

- Direct crank rewind is permanently attached (Direct crank rewind is removable when you need.)

- Roller guides are option(Specify roller position when ordering.)

- Brake System:cam-lock drag brake or spring actuated pino lck(Supplied with spring actuated pin lock as standard)

- 3~4 conductor 50 amp/600 volt rated slip ring.

- Brushes are copper graphite with copper alloy rings

- All materials are carbon steel as standard (Stainless, Aluminum and other materials are available upon request)

- Bevel Geared Crank is optional (Direct Crank as standard)

- Option: Automatic guide, Speed controller and Clutch are available.

- Series CR2000 reels are supplied without Cable. Cable assemblies will be quoted according to your request.

- Other specifications are available.

Painting : Powder Coat.

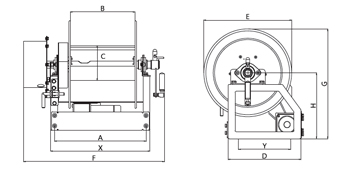

| MODEL NO. | CABLE | REEL DIMENSION | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Number of Conduct | Length | A | B | C | D | E | F (MANUAL) |

F (POWER) |

G | H | X | Y | >|

| sq | core | meter | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| feet | inch | inch | inch | inch | inch | inch | inch | inch | inch | inch | inch | |||

| CR2/63-9 | 6.0 | 3 | 50 | 340 | 180 | 200 | 390 | 665 | 450 | 465 | 500 | 275 | 300 | 290 |

| 165 | 13.4 | 7.1 | 7.9 | 15.4 | 26.2 | 17.7 | 18.3 | 19.7 | 10.8 | 11.8 | 11.4 | |||

| CR2/63-19 | 6.0 | 3 | 100 | 460 | 300 | 200 | 390 | 785 | 450 | 585 | 500 | 275 | 420 | 290 |

| 300 | 18.1 | 11.8 | 7.9 | 15.4 | 30.9 | 17.7 | 23.0 | 19.7 | 10.8 | 16.5 | 11.4 | |||

| CR2/63-29 | 6.0 | 3 | 150 | 660 | 500 | 200 | 390 | 985 | 450 | 785 | 500 | 275 | 620 | 290 |

| 500 | 26.0 | 19.7 | 7.9 | 15.4 | 38.8 | 17.7 | 30.9 | 19.7 | 10.8 | 24.4 | 11.4 | |||

| CR2/64-9 | 6.0 | 4 | 50 | 370 | 210 | 200 | 420 | 695 | 450 | 495 | 500 | 275 | 330 | 370 |

| 165 | 14.6 | 8.3 | 7.9 | 16.5 | 27.4 | 17.7 | 19.5 | 19.7 | 10.8 | 13.0 | 14.6 | |||

| CR2/64-19 | 6.0 | 4 | 100 | 540 | 380 | 200 | 420 | 865 | 450 | 665 | 500 | 275 | 500 | 370 |

| 330 | 21.3 | 15.0 | 7.9 | 16.5 | 34.1 | 17.7 | 26.2 | 19.7 | 10.8 | 19.7 | 14.6 | |||

| CR2/64-29 | 6.0 | 4 | 150 | 710 | 550 | 200 | 420 | 1035 | 450 | 835 | 500 | 275 | 670 | 370 |

| 500 | 28.0 | 21.7 | 7.9 | 16.5 | 40.7 | 17.7 | 32.9 | 19.7 | 10.8 | 26.4 | 14.6 | |||

| CR2/103-9 | 10.0 | 3 | 50 | 370 | 210 | 200 | 420 | 695 | 450 | 495 | 500 | 275 | 330 | 370 |

| 165 | 14.6 | 8.3 | 7.9 | 16.5 | 27.4 | 17.7 | 19.5 | 19.7 | 10.8 | 13.0 | 14.6 | |||

| CR2/103-19 | 10.0 | 3 | 100 | 540 | 380 | 200 | 420 | 865 | 450 | 665 | 500 | 275 | 500 | 370 |

| 330 | 21.3 | 15.0 | 7.9 | 16.5 | 34.1 | 17.7 | 26.2 | 19.7 | 10.8 | 19.7 | 14.6 | |||

| CR2/103-29 | 10.0 | 3 | 150 | 710 | 550 | 200 | 420 | 1035 | 450 | 835 | 500 | 275 | 670 | 370 |

| 500 | 28.0 | 21.7 | 7.9 | 16.5 | 40.7 | 17.7 | 32.9 | 19.7 | 10.8 | 26.4 | 14.6 | |||

| CR2/104-9 | 10.0 | 4 | 50 | 400 | 240 | 200 | 570 | 725 | 600 | 525 | 650 | 350 | 360 | 520 |

| 165 | 15.7 | 9.4 | 7.9 | 22.4 | 28.5 | 23.6 | 20.7 | 25.6 | 13.8 | 14.2 | 20.5 | |||

| CR2/104-19 | 10.0 | 4 | 100 | 610 | 450 | 200 | 570 | 935 | 600 | 735 | 650 | 350 | 570 | 520 |

| 330 | 24.0 | 17.7 | 7.9 | 22.4 | 36.8 | 23.6 | 28.9 | 25.6 | 13.8 | 22.4 | 20.5 | |||

| CR2/104-29 | 10.0 | 4 | 150 | 660 | 500 | 200 | 470 | 985 | 500 | 785 | 550 | 300 | 620 | 420 |

| 550 | 26.0 | 19.7 | 7.9 | 18.5 | 38.8 | 19.7 | 30.9 | 21.7 | 11.8 | 24.4 | 16.5 | |||

※The specifications are subject to be changed without previous notice for improvement.