Manual Rewind (HT-Series) | Hose Reel

HOME > PRODUCTS > Manual Rewind (HT-Series)

Uses : For Air,Water,Hydraulic,Lubrication,Fuel dispensing etc.

Specification

| Available Hose specifications | Max Pressure | Max Temperature | Rewind Type | Installation | ||

|---|---|---|---|---|---|---|

| Size(Inch) | Hose Material | Length(MR) | ||||

| 1/4inch~1 inch | PVC(1/TB) | 10MR~50MR | 2900psi/200bar | 212℉ (100℃) | Manual | Floor, Wall |

| Rubber(1W/B) | 30ft~160ft | |||||

Design & Structure

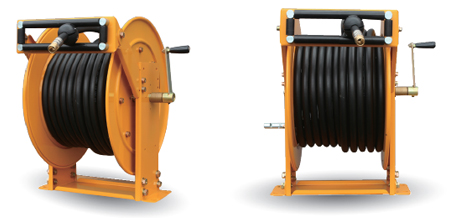

- Lightweight steel construction , compact design and versatile usage.

- Dual frame ,guide plate & ball bearing support.

- Permanent direct crank rewind .

- Roller guides is option(Specify roller position when ordering.)

- Brake System: cam-lock drag brake or spring actuated pin lock(Supplied with spring actuated pin lock as standard)

- Full flow shaft and swivel.

- Standard inlet 90° balanced pressure swivel joint(NBR Packing)

- Inlet & Outlet connection threads are female NPT (Other threads are available when you request)

- All materials are carbon steel as standard(Stainless, Aluminum and other materials are available when you request)

- HT series reels are supplied without hose, hose assemblies will be quoted as you requested

- Other specifications are available.

Painting:Powder Coat.

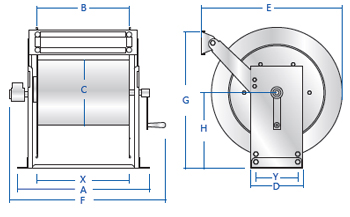

| MODEL NO. | HOSE CAPACITY | REEL DIMENSIONS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I.D | O.D | LEN GTH | A | B | C | D | E | F | G | H | X | Y | |

| mm inch |

mm inch |

meter feet |

mm inch |

mm inch |

mm inch |

mm inch |

mm inch |

mm inch |

mm inch |

mm inch |

mm inch |

mm inch |

|

| HT6-1 | 6.5 1/4 |

13 0.5 |

10 30 |

220 8.7 |

70 2.8 |

170 6.6 |

110 4.3 |

300 11.8 |

280 11 |

330 13 |

180 7.1 |

180 7.1 |

70 2.8 |

| HT6-2 | 6.5 1/4 |

13 0.5 |

15 50 |

130 5.1 |

70 2.8 |

170 6.6 |

110 4.3 |

350 13.8 |

280 11 |

385 15.2 |

210 8.3 |

180 7.1 |

70 2.8 |

| HT6-3 | 6.5 1/4 |

13 0.5 |

20 70 |

200 7.9 |

140 5.5 |

170 6.6 |

110 4.3 |

350 13.8 |

350 13.8 |

385 15.2 |

210 8.3 |

250 9.8 |

70 2.8 |

| HT6-4 | 6.5 1/4 |

13 0.5 |

25 80 |

200 7.9 |

140 5.5 |

170 6.6 |

110 4.3 |

380 15 |

350 13.8 |

400 15.7 |

210 8.3 |

250 9.8 |

70 2.8 |

| HT6-5 | 6.5 1/4 |

13 0.5 |

30 100 |

200 7.9 |

140 5.5 |

170 6.6 |

110 4.3 |

380 15 |

350 13.8 |

400 15.7 |

210 8.3 |

250 9.8 |

70 2.8 |

| HT9-1 | 9.5 3/8 |

16.5 0.6 |

10 30 |

130 5.1 |

70 2.8 |

170 6.6 |

110 4.3 |

350 13.8 |

280 11 |

385 15.2 |

210 8.3 |

180 7.1 |

70 2.8 |

| HT9-2 | 9.5 3/8 |

16.5 0.6 |

15 50 |

200 7.9 |

140 5.5 |

170 6.6 |

110 4.3 |

350 13.8 |

350 13.8 |

385 15.2 |

210 8.3 |

250 9.8 |

70 2.8 |

| HT9-3 | 9.5 3/8 |

16.5 0.6 |

20 70 |

200 7.9 |

140 5.5 |

170 6.6 |

110 4.3 |

380 15 |

350 13.8 |

400 15.7 |

210 8.3 |

250 9.8 |

70 2.8 |

| HT9-4 | 9.5 3/8 |

16.5 0.6 |

25 80 |

270 10.6 |

210 8.3 |

170 6.6 |

110 4.3 |

380 15 |

420 16.5 |

400 15.7 |

210 8.3 |

320 12.6 |

70 2.8 |

| HT9-5 | 9.5 3/8 |

16.5 0.6 |

30 100 |

300 11.8 |

240 9.4 |

170 6.6 |

110 4.3 |

380 15 |

450 17.7 |

400 15.7 |

210 8.3 |

350 13.8 |

70 2.8 |

| HT13-1 | 12.7 1/2 |

20.6 0.8 |

10 30 |

180 7.1 |

120 4.7 |

200 7.9 |

110 4.3 |

350 13.8 |

340 13.4 |

385 15.2 |

210 8.3 |

230 9.1 |

70 2.8 |

| HT13-2 | 12.7 1/2 |

20.6 0.8 |

15 50 |

210 8.3 |

150 5.9 |

200 7.9 |

110 4.3 |

380 15 |

370 14.6 |

400 15.7 |

210 8.3 |

260 10.2 |

70 2.8 |

| HT13-3 | 12.7 1/2 |

20.6 0.8 |

20 70 |

210 8.3 |

150 5.9 |

200 7.9 |

150 5.9 |

450 17.7 |

370 14.6 |

490 19.3 |

265 10.4 |

260 10.2 |

110 4.3 |

| HT13-4 | 12.7 1/2 |

20.6 0.8 |

25 80 |

210 8.3 |

210 8.3 |

200 7.9 |

150 5.9 |

450 17.7 |

430 16.9 |

490 19.3 |

265 10.4 |

320 12.6 |

110 4.3 |

| HT13-5 | 12.7 1/2 |

20.6 0.8 |

30 100 |

210 8.3 |

240 9.4 |

200 7.9 |

150 5.9 |

450 17.7 |

460 18.1 |

490 19.3 |

265 10.4 |

350 13.8 |

110 4.3 |

| HT19-1 | 19 3/4 |

27.8 1.1 |

10 30 |

180 7.1 |

120 4.7 |

250 9.8 |

200 7.9 |

450 17.7 |

350 13.8 |

490 19.3 |

265 10.4 |

230 9.1 |

160 6.3 |

| HT19-2 | 19 3/4 |

27.8 1.1 |

15 50 |

270 10.6 |

150 5.9 |

250 9.8 |

200 7.9 |

450 17.7 |

380 15 |

490 19.3 |

265 10.4 |

260 10.2 |

160 6.3 |

| HT19-3 | 19 3/4 |

27.8 1.1 |

20 70 |

270 10.6 |

210 8.3 |

250 9.8 |

200 7.9 |

450 17.7 |

440 17.3 |

490 19.3 |

265 10.4 |

320 12.6 |

160 6.3 |

| HT19-4 | 19 3/4 |

27.8 1.1 |

25 80 |

300 11.8 |

210 8.3 |

250 9.8 |

200 7.9 |

500 19.7 |

440 17.3 |

540 21.3 |

290 11.4 |

320 12.6 |

160 6.3 |

| HT19-5 | 19 3/4 |

27.8 1.1 |

30 100 |

300 11.8 |

240 9.4 |

250 9.8 |

200 7.9 |

500 19.7 |

470 18.5 |

540 21.3 |

290 11.4 |

350 13.8 |

160 6.3 |

| HT25-1 | 25 1 |

35.6 1.4 |

10 30 |

210 8.3 |

150 5.9 |

250 9.8 |

200 7.9 |

500 19.7 |

380 15 |

540 21.3 |

290 11.4 |

260 10.2 |

160 6.3 |

| HT25-2 | 25 1 |

35.6 1.4 |

15 50 |

240 9.4 |

180 7.1 |

250 9.8 |

200 7.9 |

500 19.7 |

410 16.1 |

540 21.3 |

290 11.4 |

290 11.4 |

160 6.3 |

| HT25-3 | 25 1 |

35.6 1.4 |

20 70 |

300 11.8 |

240 9.4 |

250 9.8 |

200 7.9 |

500 19.7 |

470 18.5 |

540 21.3 |

290 11.4 |

350 13.8 |

160 6.3 |

| HT25-4 | 25 1 |

35.6 1.4 |

25 80 |

270 10.6 |

210 8.3 |

250 9.8 |

200 7.9 |

550 21.6 |

440 17.3 |

570 22.4 |

320 12.6 |

320 12.6 |

160 6.3 |

| HT25-5 | 25 1 |

35.6 1.4 |

30 100 |

300 11.8 |

240 9.4 |

250 9.8 |

200 7.9 |

550 21.6 |

470 18.5 |

570 22.4 |

320 12.6 |

350 13.8 |

160 6.3 |

※The specifications are subject to change without notice for improvement.