Power Rewind

(Series 6000) | Hose Reel

HOME > NEW PRODUCTS > Power Rewind (Series 6000)

※ When order Power Rewind Type, Must choice Motor Type as below;

- MD : ELECTRIC MOTOR REWIND

- AMD : AIR MOROTR REWIND

- HMD : HYDRAULIC MOTOR REWIND

For Fueling of Aviation

| Available Hose specifications | Max Pressure | Max Temperature | Rewind Type | Installation | ||

|---|---|---|---|---|---|---|

| Size(Inch) | Hose Material | Length(MR) | ||||

| 1,1/2 inch ~ 3 inch |

NBR | 15MR~30MR | 600psi/40bar | 212℉ (100℃) | Manual & Power Motor | Floor |

| 50ft~100ft | ||||||

Design & Structure

- Drum type hose reel for Jet Refueler & Refueling Vehicle

- Standard Rewinding Speed :20MR/min

- Working Voltage : DC12V/24V(Available Change)

- Motor is installed outside of the reel

- Stable Rewinding hose by installed 4 way Guide roller. (Option)

- Bevel Gear Type for Manual Handle

- Explosion Proof Motor will be installed.

- Series 6000 reels are supplied without hose. Hose assemblies will be quoted according to your request.

- All reel materials are carbon steel as standard (But Fluid line applied SUS304 or Aluminium)

- Other Specifications are available

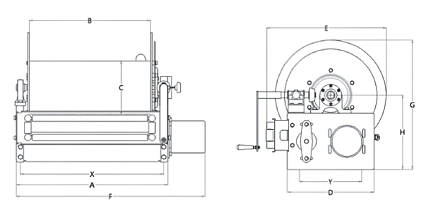

| MODEL. No | HOSE CAPACITY | REEL DIMENSIONS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I.D | O.D | LENGTH | A | B | C | D | E | F | G | H | X | Y | |

| Ø inch |

Ø inch |

meter feet |

mm inch |

mm inch |

mm inch |

mm inch |

mm inch |

mm inch |

mm inch |

mm inch |

mm inch |

mm inch |

|

| S6040-2 | 38 1-1/2 |

54 2.1 |

15 49.2 |

490 19.3 |

450 17.7 |

300 11.8 |

480 18.9 |

580 22.8 |

670 26.4 |

680 27 |

390 15.4 |

430 16.9 |

380 15 |

| S6040-3 | 38 1-1/2 |

54 2.1 |

20 66 |

590 23.2 |

550 21.7 |

300 11.8 |

480 18.9 |

580 22.8 |

770 30.3 |

680 27 |

390 15.4 |

530 20.9 |

380 15 |

| S6040-4 | 38 1-1/2 |

54 2.1 |

25 82 |

690 27.2 |

650 25.6 |

300 11.8 |

480 18.9 |

580 22.8 |

870 34.2 |

680 27 |

390 15.4 |

630 24.8 |

380 15 |

| S6040-5 | 38 1-1/2 |

54 2.1 |

30 98 |

790 31.1 |

750 29.5 |

300 11.8 |

520 20.4 |

580 22.8 |

1155 45.5 |

740 29.1 |

450 17.7 |

750 29.5 |

420 16.5 |

| S6050-2 | 50 2 |

67 2.6 |

15 49.2 |

490 19.3 |

450 17.7 |

400 15.7 |

550 21.7 |

650 25.6 |

670 26.4 |

750 29.5 |

425 16.7 |

430 16.9 |

450 17.7 |

| S6050-3 | 50 2 |

67 2.6 |

20 66 |

590 23.2 |

550 21.7 |

400 15.7 |

550 21.7 |

650 25.6 |

770 30.3 |

750 29.5 |

425 16.7 |

530 20.9 |

450 17.7 |

| S6050-4 | 50 2 |

67 2.6 |

25 82 |

690 27.2 |

650 25.6 |

400 15.7 |

550 21.7 |

650 25.6 |

870 34.2 |

750 29.5 |

425 16.7 |

630 24.8 |

450 17.7 |

| S6050-5 | 50 2 |

67 2.6 |

30 98 |

840 33.1 |

800 31.5 |

400 15.7 |

590 21.7 |

650 25.6 |

1230 48.4 |

870 34.3 |

545 21.5 |

800 31.5 |

490 19.3 |

| S6065-2 | 65 2-1/2 |

83 3.3 |

15 49.2 |

460 18.1 |

400 15.7 |

500 19.7 |

900 35.4 |

1000 39.4 |

660 26 |

1130 44.5 |

630 24.8 |

400 15.7 |

800 31.5 |

| S6065-3 | 65 2-1/2 |

83 3.3 |

20 66 |

510 20.1 |

450 17.7 |

500 19.7 |

900 35.4 |

1000 39.4 |

710 28 |

1130 44.5 |

630 24.8 |

450 17.7 |

800 31.5 |

| S6065-4 | 65 2-1/2 |

83 3.3 |

25 82 |

560 22 |

500 19.7 |

500 19.7 |

900 35.4 |

1000 39.4 |

760 29.9 |

1130 44.5 |

630 24.8 |

500 19.7 |

800 31.5 |

| S6065-5 | 65 2-1/2 |

83 3.3 |

30 98 |

660 26 |

600 23.6 |

500 19.7 |

900 35.4 |

1000 39.4 |

860 33.9 |

1130 44.5 |

630 24.8 |

600 23.6 |

800 31.5 |

| S6075-2 | 75 3 |

96 3.8 |

15 49.2 |

510 20.1 |

450 17.7 |

500 19.7 |

900 35.4 |

1000 39.4 |

710 28 |

1130 44.5 |

630 24.8 |

450 17.7 |

800 31.5 |

| S6075-3 | 75 3 |

96 3.8 |

20 66 |

610 24 |

550 21.7 |

500 19.7 |

900 35.4 |

1000 39.4 |

810 31.9 |

1130 44.5 |

630 24.8 |

550 21.7 |

800 31.5 |

| S6075-4 | 75 3 |

96 3.8 |

25 82 |

760 29.9 |

700 27.6 |

500 19.7 |

900 35.4 |

1000 39.4 |

960 37.8 |

1130 44.5 |

630 24.8 |

700 27.6 |

800 31.5 |

| S6075-5 | 75 3 |

96 3.8 |

30 98 |

860 33.9 |

800 31.5 |

500 19.7 |

900 35.4 |

1000 39.4 |

1275 50.2 |

1220 48 |

720 28.3 |

820 32.3 |

1200 47.2 |

※The specifications are subject to change without notice for improvement.