Power Rewind

(Series 5000) | Hose Reel

HOME > NEW PRODUCTS > Power Rewind (Series 5000)

For Fueling of Aviation

Design & Structure

- Single wrap type hose reel for Jet Refueler & Refueling Vehicle

- Standard Rewinding Speed :20MR/min

- Working Voltage : DC12V/24V(Available Change)

- Motor is installed outside of the reel

- Stable Rewinding hose by installed 4 way Guide roller. (Option)

- Bevel Gear Type for Manual Handle

- Explosion Proof Motor will be installed.

- Series 5000 reels are supplied without hose. Hose assemblies will be quoted according to your request.

- Other Specifications are available

※ When order Power Rewind Type,Must choice Motor Type as below;

- MD : ELECTRIC MOTOR REWIND

- AMD : AIR MOROTR REWIND

- HMD : HYDRAULIC MOTOR REWIND

Specification

| Available Hose specifications | Max Pressure | Max Temperature | Rewind Type | Installation | ||

|---|---|---|---|---|---|---|

| Size(Inch) | Hose Material | Length(MR) | ||||

| 1-1/2 inch~3 inch | NBR | 15MR~30MR | 600psi/40bar | 212℉ (100℃) | Manual & Power Motor | Floor |

| 50ft~100ft | ||||||

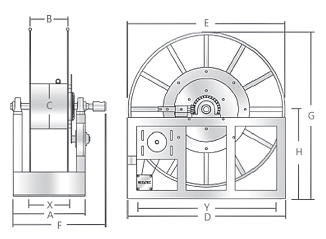

| MODEL NO. | HOSE CAPACITY | REEL DIMENSIONS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I.D | O.D | LEN GTH | A | B | C | D | E | F | G | H | X | Y | |

| mm inch | mm inch | meter feet |

mm inch | mm inch | mm inch | mm inch | mm inch | mm inch | mm inch | mm inch | mm inch | mm inch | |

| S5040-2 | 38 1-1/2 |

54 2.1 |

15 49.2 |

265 10.4 |

85 3.3 |

430 16.9 |

1100 43.3 |

1200 47.2 |

445 17.5 |

1300 51.2 |

700 27.6 |

205 27.6 |

1000 39.4 |

| S5040-3 | 38 1-1/2 |

54 2.1 |

20 66 |

265 10.4 |

85 3.3 |

430 16.9 |

1200 47.2 |

1300 51.2 |

445 17.5 |

1400 55.1 |

750 30 |

205 30 |

1100 43.3 |

| S5040-4 | 38 1-1/2 |

54 2.1 |

25 82 |

265 10.4 |

85 3.3 |

430 16.9 |

1400 55.1 |

1500 59 |

445 17.5 |

1600 63 |

850 33.5 |

205 33.5 |

1300 51.2 |

| S5040-5 | 38 1-1/2 |

54 2.1 |

30 98 |

265 10.4 |

85 3.3 |

430 16.9 |

1500 59 |

1600 63 |

445 17.5 |

1700 67 |

900 35.4 |

205 35.4 |

1400 55.1 |

| S5050-2 | 50 2 |

67 2.6 |

15 49.2 |

275 10.8 |

95 3.7 |

550 21.6 |

1250 49.2 |

1350 53.1 |

455 17.9 |

1450 57.1 |

775 30.5 |

215 30.5 |

1150 45.3 |

| S5050-3 | 50 2 |

67 2.6 |

20 66 |

275 10.8 |

95 3.7 |

550 21.6 |

1400 55.1 |

1500 59.1 |

455 17.9 |

1600 63 |

850 33.5 |

215 33.5 |

1300 51.2 |

| S5050-4 | 50 2 |

67 2.6 |

25 82 |

275 10.8 |

95 3.7 |

550 21.6 |

1550 61 |

1650 65 |

455 17.9 |

1750 68.9 |

925 36.4 |

215 36.4 |

1450 57.1 |

| S5050-5 | 50 2 |

67 2.6 |

30 98 |

275 10.8 |

95 3.7 |

550 21.6 |

1650 65 |

1750 68.9 |

455 17.9 |

1850 72.8 |

975 38.4 |

215 38.4 |

1550 61 |

| S5065-2 | 65 2-1/2 |

83 3.3 |

15 49.2 |

300 11.8 |

110 4.3 |

600 23.6 |

1250 49.2 |

1350 53.1 |

500 19.7 |

1480 58.2 |

805 31.7 |

240 31.7 |

1150 45.3 |

| S5065-3 | 65 2-1/2 |

83 3.3 |

20 66 |

300 11.8 |

110 4.3 |

600 23.6 |

1550 61 |

1650 65 |

500 19.7 |

1780 70.1 |

955 37.6 |

240 37.6 |

1450 57.1 |

| S5065-4 | 65 2-1/2 |

83 3.3 |

25 82 |

300 11.8 |

110 4.3 |

600 23.6 |

1700 67 |

1800 70.9 |

500 19.7 |

1930 76 |

1030 40.6 |

240 40.6 |

1600 63 |

| S5065-5 | 65 2-1/2 |

83 3.3 |

30 98 |

300 11.8 |

110 4.3 |

600 23.6 |

1900 74.8 |

2000 78.7 |

500 19.7 |

2130 83.9 |

1130 44.5 |

240 44.5 |

1800 70.9 |

| S5075-2 | 75 3 |

96 3.8 |

15 49.2 |

300 11.8 |

110 4.3 |

600 23.6 |

1400 55.1 |

1500 59 |

500 19.7 |

1630 64.2 |

880 34.6 |

240 34.6 |

1300 51.2 |

| S5075-3 | 75 3 |

96 3.8 |

20 66 |

300 11.8 |

110 4.3 |

600 23.6 |

1600 63 |

1700 67 |

500 19.7 |

1830 72 |

980 38.6 |

240 38.6 |

1500 59 |

| S5075-4 | 75 3 |

96 3.8 |

25 82 |

300 11.8 |

110 4.3 |

600 23.6 |

1750 68.9 |

1850 72.8 |

500 19.7 |

1980 78 |

1055 41.5 |

240 41.5 |

1650 65 |

| S5075-5 | 75 3 |

96 3.8 |

30 98 |

300 11.8 |

110 4.3 |

600 23.6 |

1900 74.8 |

2000 78.7 |

500 19.7 |

2130 83.9 |

1130 44.5 |

240 44.5 |

1800 70.9 |

※The specifications are subject to be changed without previous notice for improvement.